Who We Are

Ellwood Engineered Castings located in Hubbard, Ohio, produces gray iron castings up to 160 tons and ductile iron castings up to 60 tons in weight. Our melt shop consists of three, 55-ton coreless induction furnaces, efficiently produce accurate iron chemistries to customer specification.

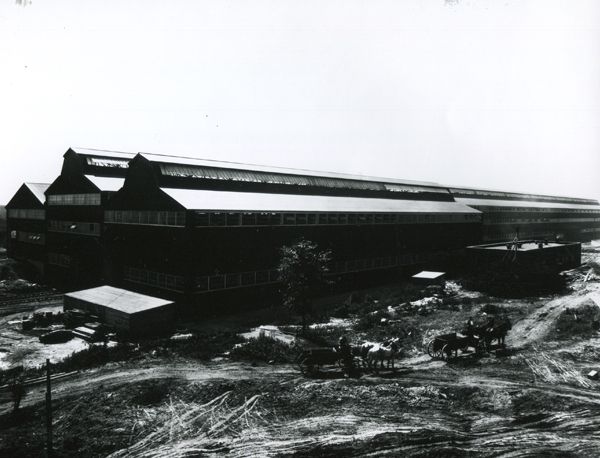

ELLWOOD Engineered Castings was born in 1992 when the ELLWOOD Group purchased the assets of the bankrupt Valley-Vulcan Mold plant on the eve of its bankruptcy liquidation. EECs major product is ingot molds used by specialty steel and alloy producers for teeming ingots, including EEC’s sister division, ELLWOOD Quality Steels, which sources all of its ingot molds from EEC. EEC is committed to quality and safety and to comply with and exceed OSHA standards. In 2009, we invested $4 million in a new fume collection bag house for the melt shop and in 2018 we replaced the silica sand in our molding process to alumina oxide sand.

Family Culture

As a family owned business, we are committed to treating our employees with dignity and respect and ensuring a safe working environment. Working at ELLWOOD provides a family atmosphere and the pride of working towards a common goal. We hold our employees to the same standards to which our customers hold us; going the extra mile to deliver quality work. Each employee is encouraged to take advantage of our ongoing education programs so they may advance their talents and achieve continued success.

Our mission is to bring a world-class product to our customers through our metallurgical expertise and customized engineered solutions. Quality is of utmost importance to meet the needs of our customers and the industries they serve. ELLWOOD Engineered Castings is committed to meeting and exceeding all standards to ensure quality, safety, and on-time delivery. We commit to applying these standards as an employer as well as, providing a world-class working environment that promotes professional growth and continuous improvement.